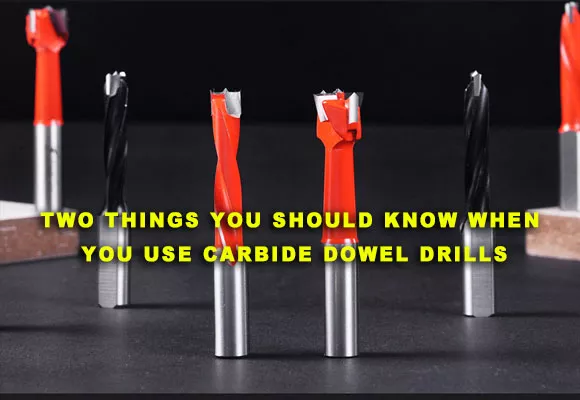

Two Things You Should Know When You Use Carbide Dowel Drills

People who like to do woodworking must be familiar with the carbide dowel drills. With high stiffness, good wear resistance, and long service life, the tungsten carbide dowel drills become more and more popular among people. The sharp edge makes the hole drilling easier, but if you run it in the wrong way, you may shorten its service life or even hurt yourself. So how do we avoid these accidents? This article summarizes the following two things to help you get away from these accidents.

First, we need to talk about some basic knowledge about dowel drills.

We know that there are many kinds of drill structures, but the reasonable structure of the tungsten carbide dowel drill bits must meet the following requirements.

1. When the bits are working, chips should be separated automatically. When the chip forms, it can be timely discharged from the hole.

2. The cutting edge should be convenient for people to sharpen several times, and the main parameters of the angle and dimension should be remained unchanged after sharpening.

3. The design of the structure of tungsten carbide dowel drill bits must meet the large productivity and good processing quality.

To know what structure the tungsten carbide dowel drills should be will help you understand how troubles happen in our daily work and it also gives a way to choose and load our drill bits.

Second, we will talk about some attention when we use woodworking tungsten carbide dowel drill bits.

1. Woodworking tungsten carbide drill bits are mounted on a professional woodworking drilling machine. So if you want to DIY some woodwork, remember to install it on the appropriate equipment.

2. Use a standard jacket. If the jacket is old or there’s a taper in the inner hole, there will not be enough clamping force, which will make the bit out of the control, and it will also lead to vibration, which may result in unqualified products.

3. Although the bit can drill almost all kinds of composite board and solid wood, it can give you a standard and smooth inner. But we still need to know that it is designed for wood and do not try to use it to cut non-wood materials such as metal, sand, and stone.

As tungsten drill bits get more and more popular among people, we should know something about these drill bits. Learning about what drill structure should be will make us know how to choose a standard drill bit, and the attention will make us know how to use the tool correctly.

I hope you have found what you need and thanks for reading.