Differences Between Square Cutting Knives and Circular Slitting Knives

The industrial machine knife is generally divided into the square cutting knife and the circular slitting knife.

The square cutting knife

Square knife cutting is to fix the blade on the knife holder of the slitting machine. During the operation of the material, the knife is dropped, so that the knife cuts the material longitudinally to achieve the purpose of cutting.

The blades of the square slitter are mainly divided into single-sided blades and double-sided blades:

1. Single-sided blades are better for slitting thicker and more rigid thick films, because hard blades are not prone to displacement under high-speed slitting machines, ensuring product quality. Single-sided blades are recommended for a thickness of 70-130um.

2. The double-sided blade is relatively soft and suitable for cutting thin materials so that the flatness of the film edge is guaranteed, and the service life can also be extended. It is recommended to use double-sided blades with a thickness below 70um.

As far as the slitting method is concerned, the square knife slitting is generally divided into two types: slot slitting and dangling slitting:

Slot slitting

When the material runs on the grooving roller, the cutting knife falls in the groove of the grooving roller, and the material is cut longitudinally. At this time, the material has a certain angle of wrap on the grooving roller, and it is not easy to drift. When slitting cast PP film or film with narrow edge material, this slitting method is commonly used to improve slitting efficiency. However, compared with the dangling slitting, its shortcoming is that the knife is more troublesome.

Dangling slitting

when the material passes between the two rollers, the blade falls to cut the material longitudinally, and the material is in a relatively unstable state at this time, so the slitting accuracy is slightly worse than the die slitting, but The slitting method is convenient for knife setting and easy to operate.

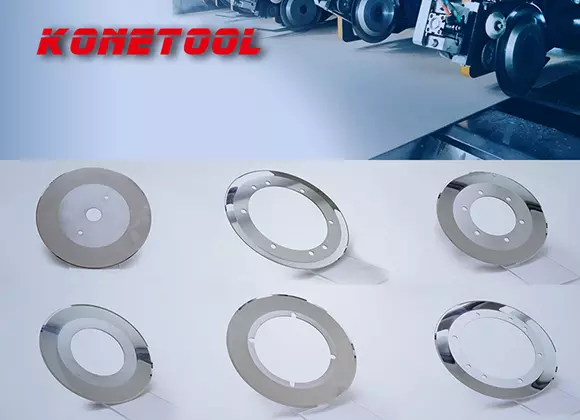

The circular knives slitting

Circular knife slitting is the main slitting method for slitting thick film, composite thick film, paper, and other materials. It is recommended to use around knives for slitting materials with a film thickness above 100um. Circular knife slitting mainly has two methods: upper and bottom knife and circular knife extrusion slitting.

The upper and bottom slitting knives can be divided into tangential cutting and non-tangential cutting:

The tangent slitting is to cut the material from the tangent direction of the upper and lower disc cutters. This kind of slitting is relatively convenient. The upper and bottom cutters can be easily adjusted according to the slitting width requirements. Its disadvantage is that the material is prone to drift phenomenon at the slit, so the accuracy is not high.

Non-tangential slitting means that the material and the lower disc knife have a certain wrap angle. The lower disc knife falls and cuts the material. This cutting method can make the material not easy to drift, and the cutting accuracy is high. But the knife adjustment is not very convenient. When installing the lower disc cutter, the entire shaft must be removed.

Circular knife extrusion slitting is not very common in the industry. It is mainly composed of a bottom roller synchronized with the material speed and a certain angle with the material, and a pneumatic slitting knife that is convenient to adjust. This slitting method can slit thinner plastic films, thicker paper, and non-woven fabrics. It is a more convenient slitting method and a development direction of the slitting method of slitting machines.

Through the above comparison, the square cutter is mainly suitable for cutting very thin plastic films and composite films, and the circular knife is suitable for cutting thicker composite films and paper.