Metal Cutting Circular Saw Blades Are Called Cold Saw Blades: Here’s Why

When it comes to processing metal, metal cutting circular saw blades, or circular metal saw blades are frequently used. Sometimes, workers in the metalworking industry also call this type of blade a cold saw blade. However, a beginner in this industry may get confused when deciding which tool to choose. Today, we will explain the reason why circular metal saw blades are also named cold saw blades to help you better understand this crucial metal cutting tool.

What is a cold saw blade?

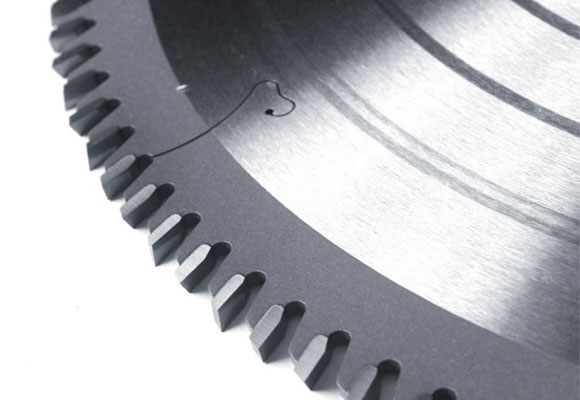

A cold saw blade is a circular saw blade that is primarily applied in metal cutting. It consists of a round, disc blade body and many cutting tips. Cold saw blades usually work with a cold saw machine. There are two types of circular metal saw blades available on the market: high-speed steel (HSS) blades and carbide-tipped (HSS) blades.

By rotation, a cold saw blade can cut ferrous or non-ferrous continuously, delivering clean and accurate cuts.

Why are metal cutting circular saw blades called cold saw blades?

On one hand, thanks to the blade geometry, there is less friction and heat generated during the cutting process. Coolant is not necessary for a cold saw. On the other hand, heat created during operation is transferred to the metal chips, and chips are removed during blade rotation. As a result, both the blade and the workpiece stay cool. The blade won’t damage the workpiece and won’t cause any warping. Therefore, professionals often call a circular metal saw blade a “cold saw blade”.

However, lubricants are still required during the cutting action to reduce friction and heat and extend the service life of the blade.

KONETOOL offers outperformed cold saw blades for aluminum and grooving cold saw blades. Our full CNC production line and rigorous quality control system ensure the high quality of every piece. Looking for a reliable supplier? Please contact us today and request a quote!