How to Select A Suitable Bottom Knife

Development of industrial slitter blades

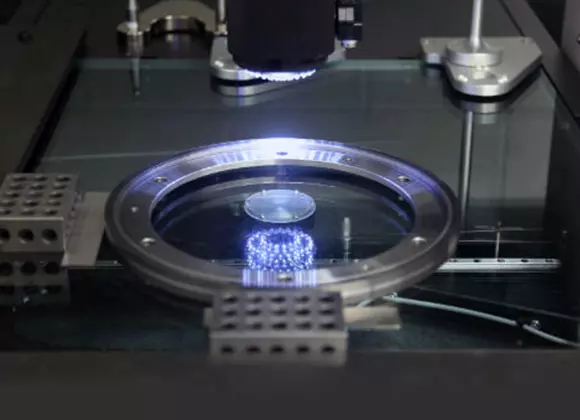

The slitting knife in China uses high-quality tungsten carbide as the raw material, and independently develops an integrated quenching technology and fine grinding processing. The slitting knife produced in this way has a sharp blade, a rounded slope, and a high surface finish. It greatly reduces friction during slitting. Make it easier to match the cutting of the knife principle.

The slitting knife is divided into an upper knife and a bottom knife, which is installed on the knife shaft of the slitting machine, and uses the rolling shear principle to slit various capacitor paper, aluminum foil, metalized film, and film with a thickness of 0.01 ~ 0.1mm, computer tape and magnetic tape.

Processing Technique

There are three common slitting process methods:

1. Trimming: A variety of materials are combined to form a technological edge. By cutting off the technological edge reserved in the process, a product that meets the technological requirements is obtained. This slitting method is mostly used for the processing of composite films and other materials.

2. Roll cutting: The whole roll of wide width is divided into multiple rolls with narrow specifications by a high-speed round knife. This cutting method is mostly used in the adhesive products industry.

3. Sub-rolling: The large-diameter material is divided into multi-roll and small-diameter materials according to the requirements of rewinding length and rewinding width. This type of slitting method is mostly used in the film substrate and flexible packaging color printing industry.

The selection of suitable bottom knives

1. Don’t pursue high-priced blades, but suitable machine blades.

There is no best blade, only a suitable blade. The advantages and disadvantages of the bottom slitting knife are relative. The key to the cutting effect of the blade is the application. This requires us to accumulate and summarize more in practice, and truly find the cutting blade suitable for ourselves.

2. Correctly handle the relationship between the performance, price, and stability of machine blades.

In the relationship between the three, the stability of the blade is life, and the high-cost performance is the goal. For example, high-speed blades are often used in high-speed cutting, but it is also a double-edged sword. While bringing people a new and efficient production method, high-priced blades have high equipment, craftsmanship, blades, blade clamping systems, etc. Requirements, so the investment before and after is relatively high. In high-speed cutting, many conditions are at the edge of the edge, and the stability of high-priced blades will become a major problem, especially in the middle and late stages of equipment use, which is more obvious when the blade accuracy decrease

Daily maintenance

In order to ensure that the bottom knife is always in a good technical state, it can be put into operation at any time, reduce the downtime of failure, improve the mechanical integrity rate and utilization rate, reduce mechanical wear, extend the service life of the machine, reduce the cost of mechanical operation and maintenance, and ensure safe production. Strengthen the maintenance of mechanical equipment.